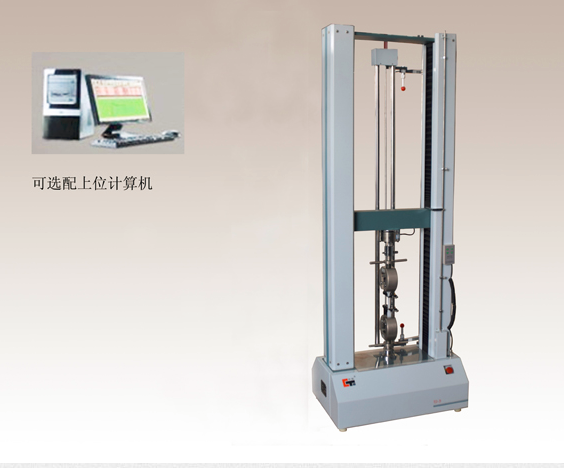

Tensile Testing Machines

After a long period of use,

Tensile Testing Machines will make the testing machine inaccurate. Now we summarize the solution to this problem. (This is only for your reference, in fact, there must be a big problem with the manufacturer)

First, Tensile Testing Machines Test Speed Calibration

When we calibrate the test speed of the test machine

(1) First note the starting position of the machine beam;

(2) Then select the speed value on the control panel (using a standard straight steel ruler to measure the cross arm travel);

(3) At the same time when starting the machine, the electronic stopwatch will start timing for one minute. When the stopwatch arrives at the same time, press the machine stop key;

(4) According to the time of the stopwatch, record the cross arm travel rate per minute rate (mm/min), observe the difference between the cross arm travel value and the ruler, and calculate the cross arm travel error value, it should not exceed ± 1% .

Second, Tensile Testing Machines calibration of various force values

Open the operation interface of

Tensile Testing Machines, click the calibration program, we first take a standard weight weight hanging lightly on the upper clamp connection, click to start the test, then record the computer display the power value, and calculate the difference with the standard weight weight, the error should be Does not exceed ± 1%, if there is a large error, it should be a problem with the sensor, try to reset the force value of the software and then perform multiple tests.

Third, Tensile Testing Machines displacement calibration

This needs to reset the current displacement, and then open the calibration interface. The interface shows the distance of the movement. This is actually an error. It should be reset and reset so that Tensile Testing Machines will be accurate in the next test.