What are the features of Universal Tester?

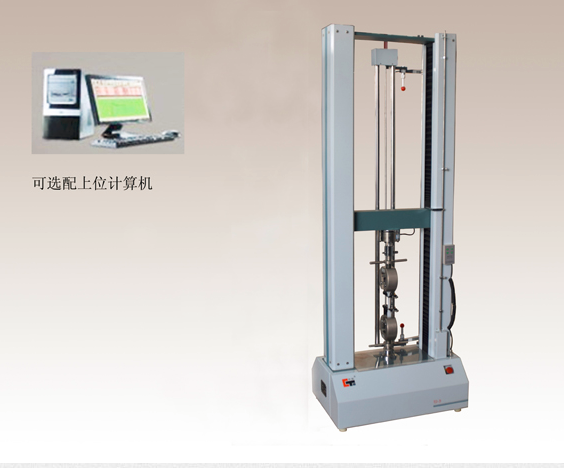

Universal tester

Inheriting the characteristics of foreign testing machines, the rigorous and perfect manufacturing process uses the TLW series of testing machines for superior quality and performance, which can meet the various needs of many industries in the field of quality control.

The test machine can be equipped with different fixtures according to different materials, which can complete the experimental contents of stretching, compression, bending, shearing, puncture, glass, etc., while the single-column bench-top universal testing machine is suitable for relatively small load and elasticity. Applications, such as biomaterials, paper, bonding materials, etc. When the material test is performed by the

Universal tester, the shape of the sample varies with the tension. In the plastic test, in order to strain the plastic material, the Universal tester is applied on the sample plate. Force.

Special tests for stretching, bending, compression or shear are classified according to the direction of the induced strain in the sample and the speed at which the force is applied.

The basic test is done by the standard electromechanical Universal tester. Different materials require different test speeds.

Dynamic and cyclical tests such as rupture growth and fatigue are generally performed over a long period of time on top of a servo oil pressure

Universal tester with a lower load.

Universal tester's most common tests for plastics to date are tensile strength and modulus, flexural strength and modulus. The ends of the specimen are clamped.

One fixture is fixed and the other is in the beam, removed from the fixture, and the specimen is pulled until it breaks, then the beam automatically stops.

The specimen was placed on the two supports on the

Universal tester's fixed base for bending tests. For this test, the beam was moved in the opposite direction to the tensile test, pushing rather than dragging the unsupported center of the specimen. Until it bends and may break.